I have been thinking about this post since I started my current job 4 years ago. After learning about the business of hardwood floors, I was shocked to learn how much was involved in choosing the best hardwood floor for your home. I have pretty much broken it down to the following. Of course, like all things, there are many more aspects to consider. But, this is a great place to start.

- Species – Species dictates the appearance, stability and durability of hardwood floors. Each species has a specific look and color associated with it. Species is also graded on the Janka Scale. This link will go into detail, but basically, each species is tested by the force of driving a small steel ball into the wood until half of ball is embedded into the wood. In Mom terms, how hard does your toddler have to push down on his Thomas The Train to completely destroy your hardwood floors? Although hardness should be considered when purchasing hardwood floors, it is not the only thing to keep in mind. Especially in a southern humid environment; stability is equally if not more important. Stability refers to how the species of hardwood responds to heat and humidity. AKA gapping in the winter and swelling in the summer.

- Width – No matter the species, the width of the floor is going to influence how the floor performs. The smaller the width, the less likely you will have issues with gapping and cupping. Hardwood floors used to be trees, and trees are round, so a floor that is wider is more at risk to bend in response to environmental factors.

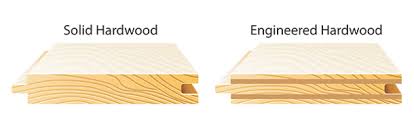

- Solid vs Engineered Hardwood Floors – We have established you are more likely to have issues if your floors are wide, but this only matters if the floor is solid. A solid hardwood floor is the same material throughout the entire thickness of the floor. Width and it’s effect on dimensional stability, is thrown out the window when considering engineered hardwood floors. Engineered floors refer to a top layer of hardwood (the wear layer) affixed to several layers of plywood (the substrate) that are perpendicular to one another counterbalancing movement. If you buy a quality engineered product, you can sand these floors as much if not more than a solid hardwood floor.

- Thickness – A solid hardwood floor is typically 3/4” thick. This is the “standard” to which everything else is compared. A 3/4” thick solid hardwood floor can be sanded about 8 times. The amount of times you can sand your floor is important especially when you want to live in the home a long time and you don’t plan on replacing the floors. Engineered floors come in a range of thicknesses. When purchasing, make sure the thickness of the floor, and especially the wear layer (top layer of hardwood), directly corresponds to how you plan to live in the home and/or the quality your buyer expects if you are ever going to sell the home.

- Color – Color starts with species. Some species are dark (walnut) and some are light (white oak). If you are born a blond, it’s a lot easier to die your hair darker than if you were born with black hair and want to go blond. The same is true with hardwood floors. Color can also be added with a traditional stain, a tented oil or a chemical reactive stain. However, the starting color of the species will typically come through no mater what color you add.

- Finish – Finish is the top layer that protects or finishes the floor. The most common finishes are water based polyurethane, oil based polyurethane, moisture cured urethane, penetrating oils and Aluminum Oxide. Houselogic.com does a terrific job of explaining the pros and cons of each finish. Choosing the right finish is a lot like dating. You might be drawn to a certain look, but if it doesn’t fit in your lifestyle, looks fade fast!

Our new house had a mix of flooring. It had carpet in most of the rooms, Brazilian cherry in the foyer, dining and kitchen and red oak in the den. I felt it was important to have the same flooring throughout. Keeping a consistent flooring surface creates continuity in design and it also makes your home look bigger. We replaced all of our floors with 3/4” thick x 7” wide Engineered European White Oak from Lighthouse Plank Flooring. They were finished with a water based sealer and a water based satin polyurethane. Check out the before and after pics below!

Before pictures of the master from the listing photo and during renovations:

After pictures of our bedroom with new hardwoods:

Before pictures of the kitchen from the listing photo and during renovations:

After pictures of the kitchen:

Before pictures of the den from the listing photo and during renovations:

After pictures of the den:

Companies you should check out for flooring:

John Griffiths Hardwood Flooring

Reclaimed DesignWorks

Lighthouse Plank Flooring